Once the old programs are no longer available, our job therefore is a complete redesign for the system. As a verified system integrator in the development and installation of custom control and automation systems, CTI SUPPLY fulfils the customers with a wide range of requirements achieve enhanced productivity and throughput. PLCs and HMI play an […]

Author Archives: CTI Supply

Water supply involves a number of components such as the water source, treatment plant, service reservoirs and the distribution system. Water utilities are responsible for the operation and maintenance of water treatment plants and distribution networks, crucial for ensuring reliability and quality of supply. This study session begins by concentrating on how adequate operation and […]

Against the backdrop of the water supply management, the pressure for municipalities and plants to efficiently treat water is greater than ever. It’s more necessary for water treatment and supply plant to regularly analyze the plant’s water treatment performance and ensure systems are operating with the most efficient equipment and technology. When water treatment plants […]

SIWA Smart Water Management to control and optimize water supply and sewer networks from one central point Using data from sensors and special mathematical algorithms, SIWA solution monitors your plant and indicates leaks. It optimizes the efficiency of pumps, aerators and compressors and controls waste water flows – resulting in increased cost and energy efficiency. […]

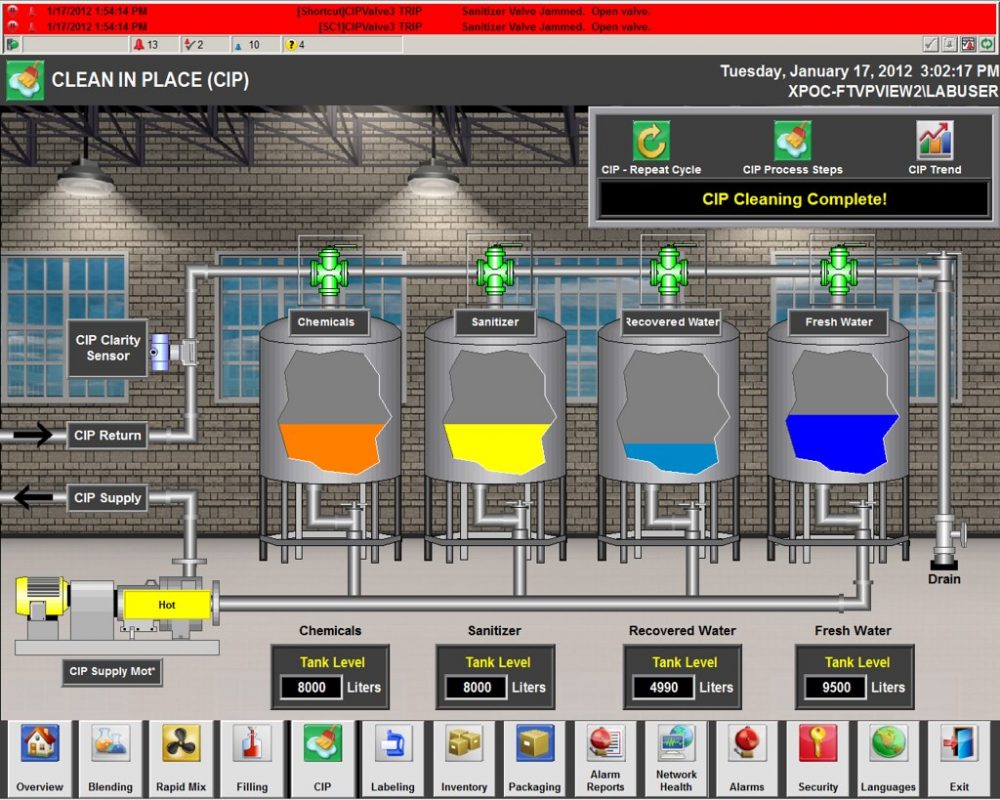

Leveraging the FactoryTalk® Integrated Production and Performance Suite from Rockwell Automation, Hamilton City Council implemented an upgrade to their supervisory control and data acquisition (SCADA) system at the plant, enhancing the ability of key stakeholders to make informed decisions, improve performance efficiency and meet regulatory compliance. The Waikato River — the longest river in New […]

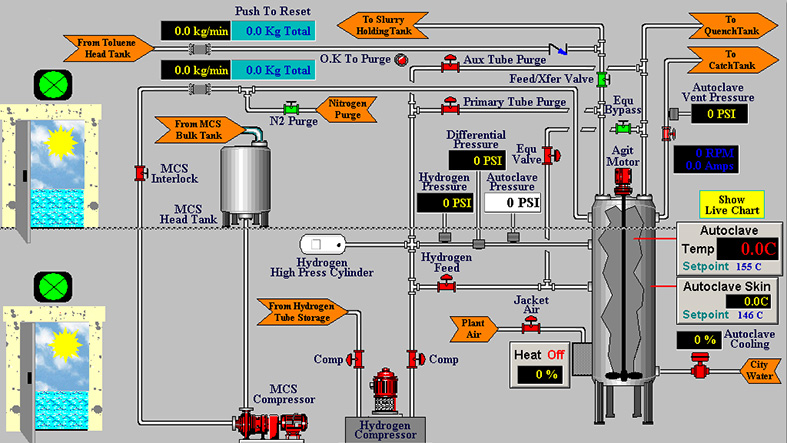

The SCADA system improvement concept was developed as a universal means of remote access to a variety of local control modules, which could be from different manufacturers allowing access through standard automation protocols. In practice, large SCADA systems have grown to become very similar to distributed control systems in function, but using multiple means of interfacing with the plant. They […]

Overview of Ultrasonic Machine Ultrasonic machine is favored by the market because it can improve the processing precision of products, save a lot of labor costs and improve production efficiency. Various machinery consist of many types and the specific design can be customized according to customer requirements. Ultrasonic mask machine Ultrasonic hot drilling machine Ultrasonic […]

While laboratory analytical measurements are required to establish the proper treatment process in the water treatment plant, process control systems and on-line analytical instruments have been developed to assist the treatment plant operator in the control of the treatment process. Process automation can be separated into 2 types – continuous (or analog), and sequential (or […]

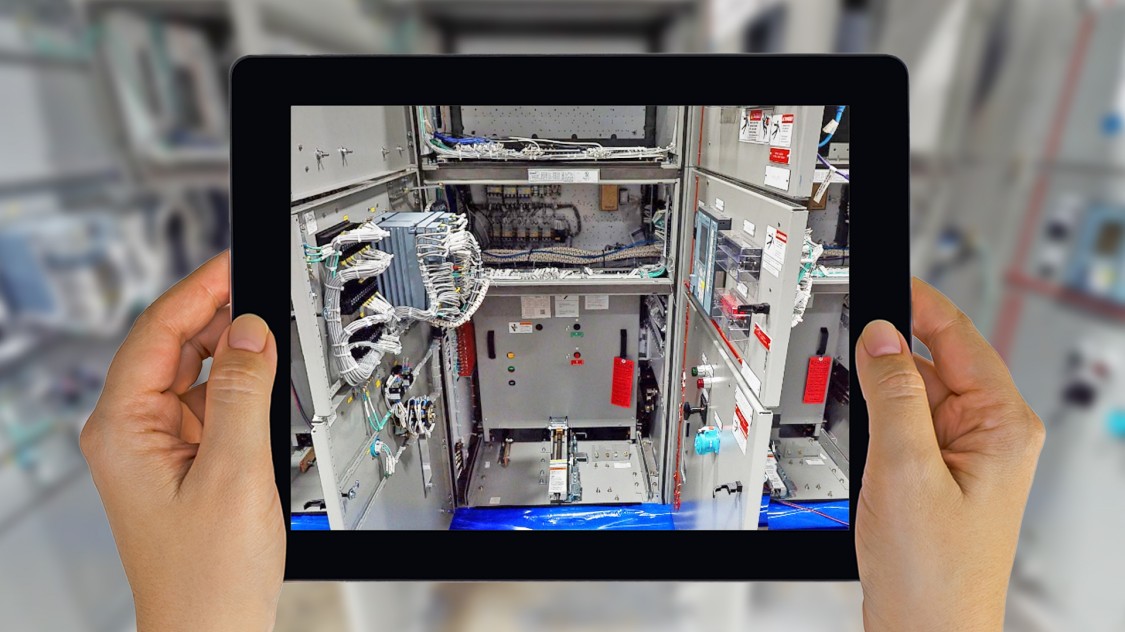

FAT (Factory Acceptance Test) is carried out in order to demonstrate that the system and its components function properly, that manufacturing, assembly, configuration and software generation are done correctly and that system performance is in compliance with the approved functional specifications and relevant documents. The same should be also carried out for DCS. The main […]

When adding, modifying, or upgrading a system, many critical infrastructures conduct a factory acceptance test (FAT). A FAT includes a customized testing procedure for systems and is completed before the final installation at the critical facility. Because it is difficult to predict the correct operation of the safety instrumented system or consequences due to failures […]

Tiếng Việt

Tiếng Việt