Contents

Overview of Ultrasonic Machine

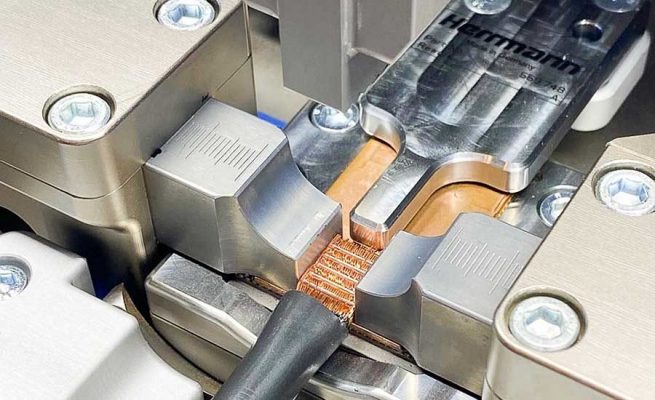

Ultrasonic machine is favored by the market because it can improve the processing precision of products, save a lot of labor costs and improve production efficiency. Various machinery consist of many types and the specific design can be customized according to customer requirements.

- Ultrasonic mask machine

- Ultrasonic hot drilling machine

- Ultrasonic lace machine

- Ultrasonic slitting machine

- Ultrasonic non-woven bag machine

- Ultrasonic plastic welding machine

- Ultrasonic shearing machine

- N95 mask machine

- Ultrasonic duckbill mask machine

- Ultrasonic without Textile bag machine

- Ultrasonic cleaning machine

- Ultrasonic medical filter welding machine, etc.

Ultrasonic Machine Application

Ultrasonic machine used in ultrasonic processing, several existing operating frequencies are 15KHZ 18KHZ, 20KHZ, 40KHZ. The principle is that the amplitude of the longitudinal wave is used to transmit the amplitude to the gap of the plastic part, and under the condition of pressure, the molecules of the contact parts of the two plastic parts or other parts with the plastic part collide with each other to melt, so that the contact plastic is fused.

Way of Maintenance

The mechanical appearance of cleaning and maintenance

If it has not been used for more than one week, please cover it with a dust jacket (plastic bag). When not in use for a long time, please wipe the appearance of the machine, oil up, and cover the attached machine cover, and put it in a dry and ventilated place. Every time the welder is used for one month, the sliding part should be cleaned and reapplied with high-quality grease. Except for the lubricating oil that has been collected by the lifting screw, no oil is required in other parts. The top of the control box should be touched every month, and the dust in the box should be cleaned with a clean, air-free air gun to keep the parts in good condition.

If there is dust in the appearance, wipe it with a clean cloth. Use dry compressed air to blow the dust inside the machine every six months. When cleaning the side plates and surfaces of the welder, it is forbidden to use various fluxes. Use a neutral detergent and wipe gently. The welding head itself is determined by the weld and must match the resonance of the vibration system. The welding head, the bottom mold and the work are often kept clean. The machine should be wiped regularly, but it should not be cleaned with liquid. Do not press or place fluid on top of the vibration box (recommended: safe deposit box).

Ultrasonic spot welding machine welding should not be placed in a place with humidity or dust and excessive heat. Do not place fluid on top of the machine (recommended: heat exchanger). Always pay attention to clean and clean, but do not use liquid cleaning.

The precautions during operation Maintenance methods

During operation (loaded state), the vibrating table should not exceed the red zone (when the standard welding machine is used). If the indication is exceeded, reduce the pressure, reduce the number of output segments, and adjust the sound wave adjustment. Press the ultrasonic check switch to press it intermittently.

Do not press it for more than three seconds to maintain the vibrator life. The vibrator and the vibration machine of the ultrasonic welding machine have high-voltage lines. Do not perform maintenance in the machine except for external operation adjustment. When transporting the machine, the vibration box should be separated from the body (disassemble the cable socket), and care should be taken not to be hit.

The Preventive Maintenance Schedule

The grounding wire should be grounded and not connected to the ground of the power supply to prevent high voltage leakage. Do not press the welding head of the ultrasonic welding machine to avoid burns. If it is dangerous during automatic operation, please press the emergency rise button.

- Regular inspection and maintenance methods:

Regularly check the internal vibrator output line for wear. When the filter cup reaches 1/3 water level, please remove the water. Keep your machine position safe at all times. Keep the air in the workplace unobstructed, and the ambient temperature should not be too high (below 40 °C). Regularly smear the grease, such as lifting grooves and screws, and keep it clean. Check regularly if the wire is loose.

- Mechanical effect:

The mechanical effect is that the current will generate a magnetic field, and the huge short-circuit current will generate huge electromagnetic stress. The support part of the circuit device may cause mechanical damage and the effect of the ultrasonic wave moving forward in the medium. Ultrasonic mechanical effects are the primary primary effects of ultrasound, regardless of the magnitude of the ultrasound. It has two principle sources:

One is the mechanical effect of the advancement of ultrasound in the medium, called the mechanical effect in the traveling wave field. In addition, the mechanical effect of ultrasound caused by reflection when the medium propagates is called the mechanical effect in the standing wave field.

The former causes the positive pressure and negative pressure generated by the alternating compression and extension of the various points in the human tissue due to ultrasonic vibration, and the huge acceleration obtained by the communication, under the general treatment intensity, the pressure change in the human tissue is about ± 304kPa (3 atmospheres), when the ultrasonic frequency is 1MHz, the pressure per cell is about 0.4~0.8Pa (4~8mg).

The latter is formed by the interference of the oscillating wave and the forward wave, which can affect the tension and pressure of the human body, so that the body mass can obtain a greater acceleration, so that different masses of ions in the dissociated liquid can obtain different motion velocities.

The ions with large particles lag behind the ions with small particles, and the relative movement between the ions occurs, generating friction and generating energy.

It can be seen that the mechanical effect in the standing wave field is mainly caused by the difference in the moving speed, and it is even larger than the pressure change in the ultrasonic mechanical effect. It is known that when the tissue is subjected to ultrasound, the ultrasonic field generated by the transducer vibration generates a one-way motion, and the motion is repeatedly and periodically oscillated in the tissue. This one-way flow of sound is particularly obvious at the surface of the bubble, the cell and the cell membrane.

Ultrasonic welding machine maintenance points

1. The welding head, bottom mold and work of the ultrasonic welding machine are always kept clean.

2. Regularly check if the wire connector is loose.

3. Regularly clean the air filter. Use a cleaning agent or water. Do not use volatile flux.

4. The machine should be wiped regularly, but it should not be cleaned with liquid. Do not press or place fluid on top of the vibration box.

5, the workplace to keep the air flowing, the surrounding temperature can not be too high. (40 degrees or less)

6. Lift the clearing tank, screw and other regular yellow grease and keep it clean.

7. When handling the ultrasonic welding machine, the vibration box should be separated from the body (disassemble the cable socket), and the handling must be careful not to be hit.

8. When not in use for a long time, please wipe the appearance of the machine, oil up and maintain, and cover the soil cover with the machine, and put it in a dry and ventilated place.

9. The upper cover of the ultrasonic welding machine control box should be opened every month, and the dust in the box should be removed with a clean air pump without water. In order to keep the parts cool and ventilated.

To the processing purpose, Ultrasonic machines because of their ability to improve product processing accuracy, save labor costs, and increase production efficiency, they are favored by the market.

CTI SUPPLY – Maintenance Technical Support

CTI SUPPLY maintenance engineers at the on-site manufacturing plant ready to handle and resolve technical issues of industrial production lines. In particular, the unit provides a variety of maintenance and repair services as followings:

- Electrical automation system applied with PLC/SCADA/HMI Foundation

- Food processing and packaging system

- Automated assembly system

- Semi-Automatic to Fully Automatic equipment

- Multiple Hydraulic and pneumatic systems

- Automatic conveyor system

- Pressing, Fine Blanking, Rolling, Cutting, Bending, Ultrasonic Welding Machine

- Hardening and Tempering Furnace system

CTI SUPPLY improves the profitability for clients by performing different scope of installation, commissioning and maintenance services under OEM’s instruction at the customer’s site. The scope of activities is diverse, our team experienced with many years of designing, programming and maintaining machinery in the oil and gas industry and large European manufacturing plants in Vietnam. In particular, we plays the role as local technical support on site for customers under OEM authorization with in-time flexibility and activeness.

Are you looking for a ultrasonic welding machine maintenance team? Contact us.

Tiếng Việt

Tiếng Việt