Fine blanking, which was developed in Switzerland in the 1950s, added a slower but very precise stamping process that provides all cut surfaces with a smooth cut that meets the highest demands. The fine blanking process offers significant advantages over stamping. Compared to conventional stamping, fine blanking offers many benefits. It is more and more […]

Author Archives: CTI Supply

The Importance Of Proper Manufacturing Equipment Service Regular manufacturing equipment maintenance is the key to preventing catastrophic equipment failure. It can pay off in the long run in the form of increased operational efficiency and reduce cost. Unexpected equipment failure in a manufacturing plant can interrupt the production schedule and lead to costly downtime that […]

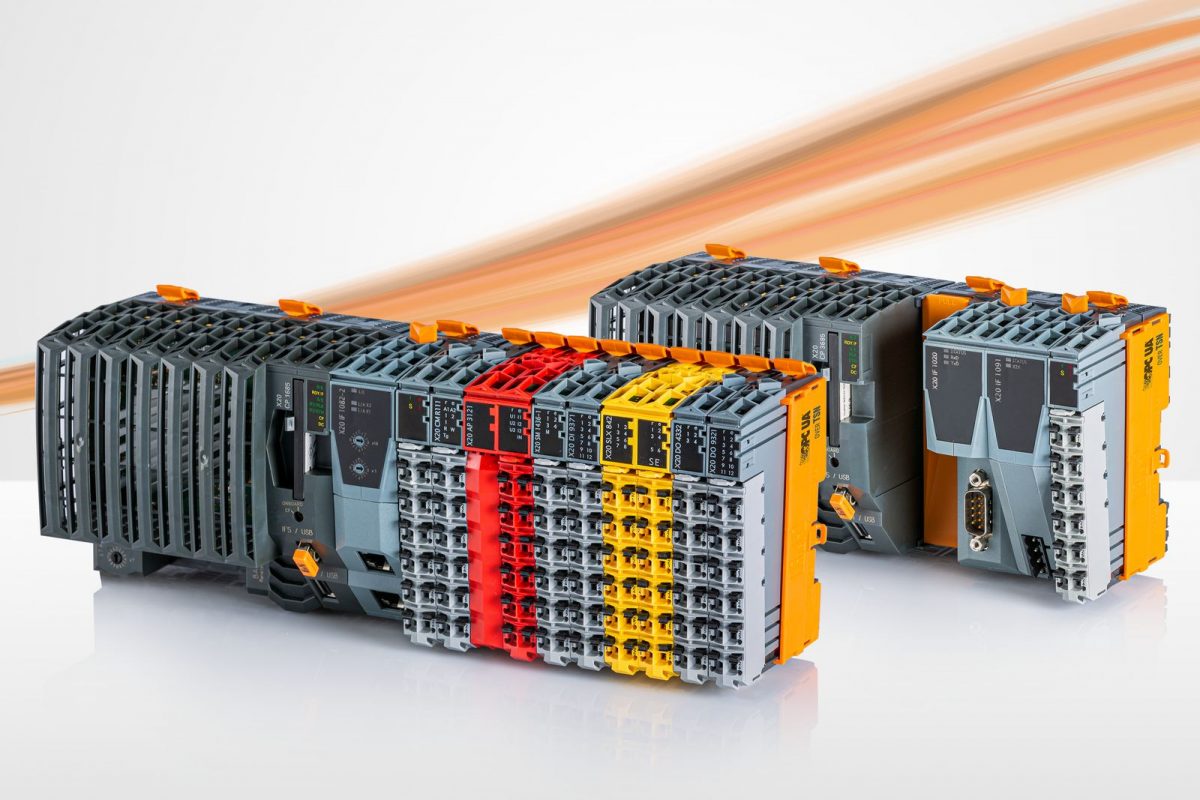

The Top PLC Manufacturers in the Industrial Automation Industry The majority of PLC manufacturers involved in the industrial automation industry are also heavily involved in manufacture of other industrial automation equipment. Some have become large conglomerate organizations not only involved in industrial automation but other sectors such as energy, infrastructure, healthcare, automotive, aviation, robotics, mobility, […]

What’s the difference between OEM Maintenance and Third Party Maintenance? A comparison between support through original equipment manufacturers OEM Maintenance and third party maintenance providers (TPMs) might show you some of the basic differences between the two, but this comparison is going to dig a little deeper into the specifics of what you can expect […]

Outsourcing is one of the most effective methods to have good software at a reasonable price. Having an in-house team to develop a software can be costly as well as hectic thus outsourcing is the way to go. You can have the best quality product at a much lower programming cost. Introduction It is the […]

Basically, virtual commissioning is the practice of using “virtual” simulation technology to “commission”—design, install or test—control software with a virtual machine model before you connect it to the real system. Using the TIA Portal to simulate, validate, and optimize controllers and machines Machine development is usually sequential: Mechanical design, electrical design, and automation are performed […]

When It’s Time to Install Your Next Production Line, Is It Best to Engage a Machine Builder or an Automation System Integrator as a Partner? Many manufacturing plants outsource all or part of major capital projects, such as greenfield plants or new production lines. When these projects include a number of machines and a high […]

NKS Flux Chipper Best for graving stones, removing paint, rust, welding flux and chipping work Usable with small compressor. Specifications NKS Kelen Removing mad. Rust on construction machines, concrete on concrete panels, Peeling off tiles and P tiles, chipping highway road. Specifications NKS Sand Rammer Tamping casting sand, fireproof clayware, patching for smelter, tamping soil for […]

The Open Systems International acquisition complements Emerson’s portfolio and helps customers in discrete and hybrid end markets accelerate digital transformation. The Progea Group acquisition expands Emerson’s software portfolio, enabling the rapid shift toward the smart grid of Open Systems International. Emerson (NYSE: EMR) announced it has completed the acquisition of the Progea Group, an industry-leading […]

Strong relationships can enable both to prosper as OEMs and suppliers broaden their scope and educate manufacturers about fast-moving and complex automation advancements. It means they may not have the time or resources to stay informed about. Automation technology advancements have increased so quickly in the last decade. Thus, the speed and quantity of new […]

Tiếng Việt

Tiếng Việt