Electrical & Automation – Thiết Bị Điện Tự Động Hóa

Description

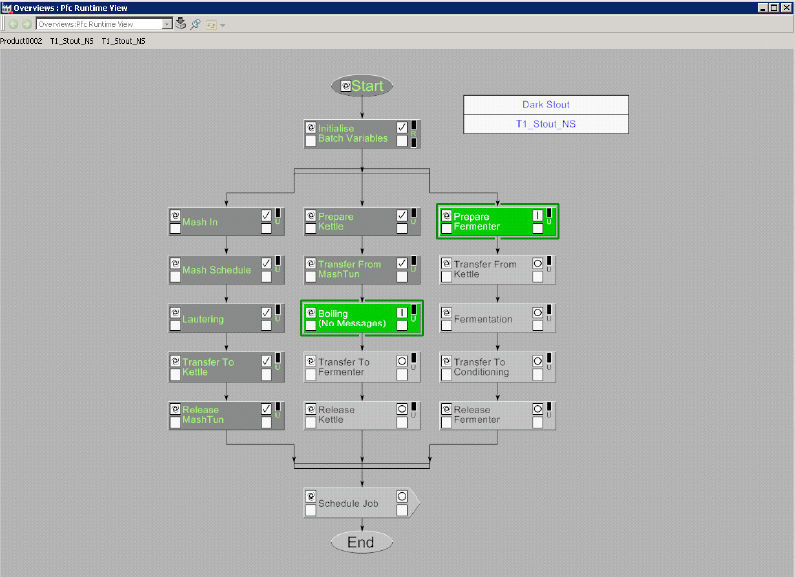

System 800xA Batch: Recipe editor

Improved product quality and reduced processing through dynamic parameters in control recipes.

Superior operational and control capabilities

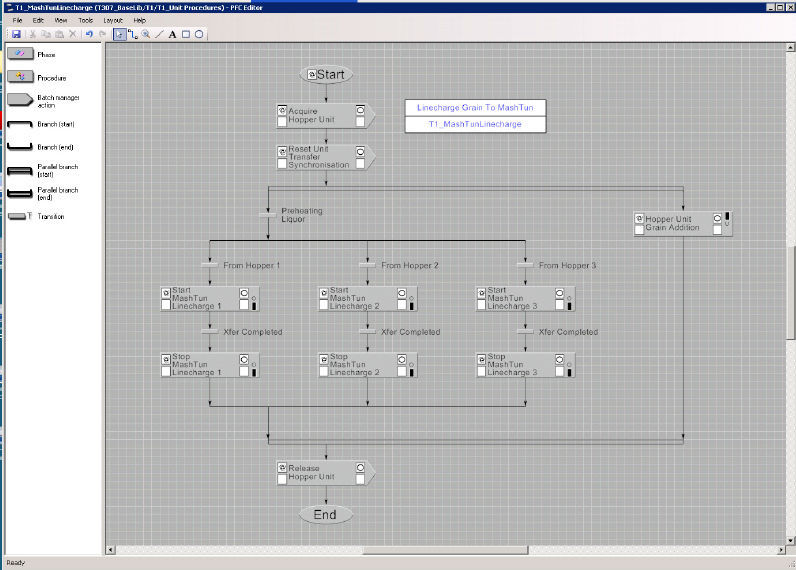

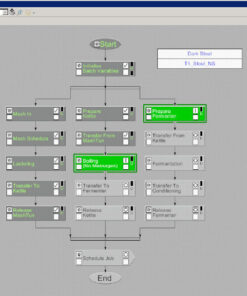

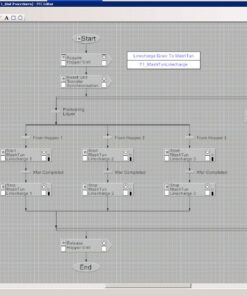

The master batch recipe procedure, and all nested procedure levels are configured graphically in 800xA Batch Management. The diagram is a Procedure Function Chart (PFC) based on ISA88 standards. The following information can be specified for each individual batch recipe:

Procedure

Formula

Equipment requirements

Header and other information

Superior operational and control capabilities with configuration of conditional transitions, logical branching, parallel branching, looping structures and dynamic block labels.

Re-usable procedure building blocks can is easily be managed and created. Unit procedures and operation procedures can be used in multiple higher level procedures. When a modification is made to one of these lower level procedure building blocks, all procedures using that block are updated.

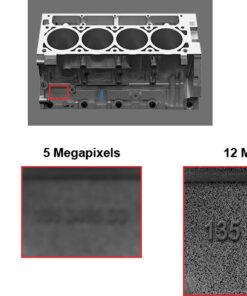

Improved flexibility with real-time formula calculation

Formula information includes input parameters, process parameters, and output parameters. 800xA Batch Management supports the specification of formula information at any level of the procedure. Dynamic, real-time calculation of recipe parameters during the batch production execution is possible which provides a tremendous flexibility.

English

English

Đánh giá

Chưa có đánh giá nào.