Contents

SCHUNK Life-Science Partner

In the “Science of Life” – the life science – the biotechnology, medical technology and pharmaceutical industry work together. The aim of this multi-discipline collaboration is to work towards a future with more focus on health and safety, while producing new medical technology products, treatment methods and medicines. The manufacturing industry has a key position here – manufacturing uses modern processes for producing high-quality products in the following areas:

- MedTech

- MedDevices

- Lab Automation

- Pharma

Industry Disciplines

MedTech

The SCHUNK Portfolio for Assembly Handling

The medical technology sets high standards on product manufacturing. Machines, plants and components of the manufacturing industry which are used for manufacturing devices and consumables, are subject to defined conditions in terms of lubricants, robustness and longevity. SCHUNK supplies the manufacturers of medical technology systems or the manufacturing industry of medical goods with high-end products and putting the focus on H1-compliant lubrication, robustness and absolute process reliability. The pneumatic MPG-plus gripper for small components is such an example. It handles any medical technology parts and products safely and gently.

MedDevices

High-end Components for Use on Humans

Medical devices are products, objects and substances that are used in direct contact with humans to examine, treat or monitor. SCHUNK offers top-quality products for surgery robots, care and service robots, exoskeletons and devices in the field of orthopedic rehabilitation. With their high-quality design the SCHUNK modules ensure the necessary reliability and durability for delicate tasks needed for use on humans. The necessary sensitivity of a surgery robot for example is ensured by the incorporation of force/torque sensors.

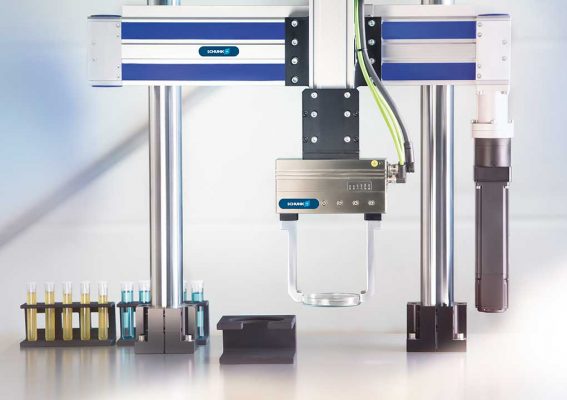

Lab Automation

Efficient and reliable Laboratory Processes

In a lab it is all about systematically recurring processes. The lab operators offer analytical and diagnostic products and services with the focus on efficiency, safety, care and profitability. Handling of reagents, measuring technology and analytical equipment are everyday topics. SCHUNK supplies numerous, ideal components for laboratory equipment and handling systems for lab automation. They are compact and simply modular systems which can be custom assembled and used in this industry. The best application example is the unique high-end portfolio of mechatronic products with 24 V supply. It offers easy implementation and operation for the manufacturer and therefore ensures reliable, efficient and automated operation of the laboratory and analytical devices.

Pharma

Cleanroom compatible Performance Booster

In large-scale production of pharmaceutical end products such as tablets, powders, creams and liquids, purity and quality are always top priority. Transparent and well-structured processes supported by reliable and powerful automation units are required for the highest possible efficiency in terms of processes and cost-effectiveness. In the pharma industry SCHUNK sets benchmarks with top-quality products and a comprehensive application knowledge of increased plant performance. SCHUNK facilitates handling and machining of filigree workpieces such as tablet blisters, flacons and ampoules with cleanroom compatible, customized solutions in a simple clean design. The EGP electric gripper series for small components is perfectly suited for the safe and delicate grip of syringes and cannulas.

Application Cases

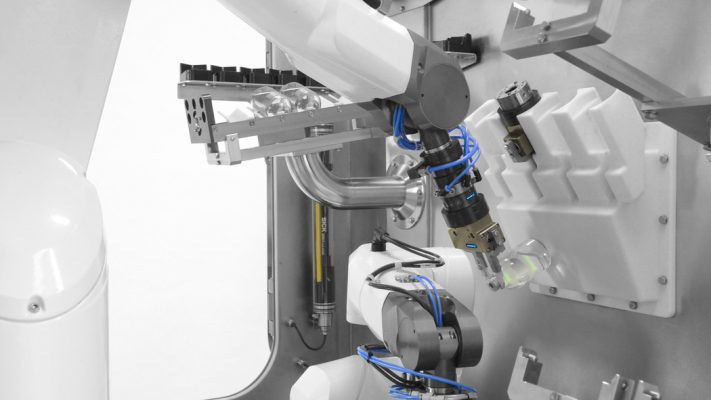

Automated handling and preparation of pharmaceuticals

Workpiece: Vessels and containers for medications in liquid and powder form

Task: Reliable gripping of different containers during the preparation of pharmaceuticals

Solution: A robot with a change system SCHUNK SWS is used for fully automated preparation of medications. Depending on the container to be gripped and the process step to be carried out, it exchanges different tools, including various SCHUNK grippers. In this way, patient-specific preparations or small and medium-sized series can be realized.

Customer benefits: SCHUNK grippers reliably handle various containers such as syringes, glass vials or IV bags during different process steps. Depending on the requirements and task, the robot flexibly exchanges the appropriate tool.

Safe handling and holding of blood collection tubes

Workpiece: Blood collection tubes (monovettes)

Task: Reliable gripping and holding of delicate blood collection tubes during the untwisting process

Solution: During automated sample taking, the electrical gripper for small components SCHUNK EGP picks up and centers the blood collection tube. The gripper reliably holds the sensitive plastic tube while the screw cap is being opened,so that it cannot rotate with the cap.

Reliable grippers for medical applications

Experts in more and more industries discover the benefits of automation and robotics, and this also applies to the medical technology. Previously manual and sometimes error-prone processes can be automatically completed within a short period of time with the help of automation, and associated processed can be optimized. SCHUNK has established a team of specialists to explore new fields of automation applications and to find innovative automation solutions with agile working methods. An exemplary gripper for the use in ventilators for COVID-19 patients shows where you can find potentials.

The concept was developed in close cooperation with physicians from the University of Tübingen, and is based on automated ventilation via a resuscitator, which can be very easily set up and adjusted via touchscreen. A pressure between 4 mbar to 50 mbar, a volume from 200 ml to 800 ml, a frequency from 5 to 80 cycles per minute, and an inspiratory time I:E of 1:2 to 4:1 can be adjusted. Therefore the system covers all relevant parameters to ensure artificial ventilation of COVID-19 patients. SCHUNK uses proven sensor systems and mechatronic grippers with additively manufactured gripper fingers from its own product line as well as an industrially established control unit for the patent-pending system. Proper function of the device is permanently monitored and any malfunction such as leakage or obstruction of the ventilation hose are immediately signaled. Due to its design, it is possible to switch between manual and automated ventilation in a very short time.

A look at other industries

“This application illustrates how versatile and reliable our gripping systems components can be used in the field of medical technology and other industries,” underlines Timo Gessmann, Chief Technology Officer (CTO) at SCHUNK, and encourages the creative use of the potential of automation solutions. “The modular design of our software and electronics enables us to implement new functions and services within a very short time. With our newly formed team for new types of automation applications we are able to successfully implement such customer- and solution-oriented products and solutions from the development up to certification.”

Exact force measurement in rehabilitation

Workpiece: Lambda rehabilitation robot

Task: Precise force/torque measurement of smallest patient influences

Solution: SCHUNK FT-AXIA sensors are used to measure the forces acting on the foot pedals of the rehabilitation robot. The feedback to the robot allows interactive rehabilitation programs.

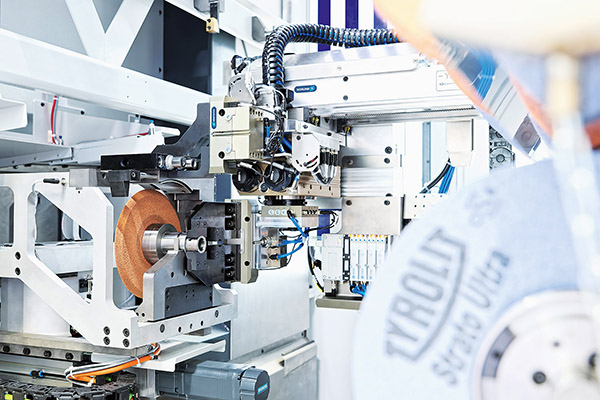

Reliable gripping for the production of angioplasty balloons

Workpiece: Production machine for catheter balloons

Task: Reliable gripping of the hose to be machined without damaging it

Solution: Two SCHUNK PGN-plus 64 grippers with ISO clean room certification grip a plastic tube, which is formed into a balloon catheter using heat.

Tiếng Việt

Tiếng Việt