The PLC has been used ever since to make logic based decisions in automated industrial processes. Despite their resilience and rugged design, PLC-based control systems can still break down and their failure can lead to costly downtime. CTI SUPPLY hereby discusses the top causes of PLC control system failure and how the risks can be […]

Author Archives: CTI Supply

Mass finishing is a group of manufacturing processes that allow large quantities of parts to be simultaneously finished. The goal of this type of finishing is to burnish, deburr, clean, radius, de-flash, descale, remove rust, polish, brighten, surface harden, prepare parts for further finishing, or break off die cast runners. The two main types of […]

What is a Parts Cleaning Machine? A parts cleaning machine/parts washer is a mechanical device designed to remove dust, grit, grime, oil, miscellaneous debris, dirt, paint, chemical and other contaminating substances on product’s surface in preparation for their use in assembly operations, packaging, or coating manufacturing industry. The basic function of a parts washer is […]

Pulp and paper mills are conducive to harsh environments producing lots of dust and heat. Elimination or reduction of the effects of heat and dust is critical to the healthy performance of pulp and paper mills. A preventive maintenance campaign means that equipment failures which result in production downtime and cut profits can be kept […]

Industrial manufacturers strive for minimizing production line downtime, which is why it’s essential to improve your SMT line productivity with preventative maintenance strategies. CTI SUPPLY hereby points out the importance of SMT line equipment preventive maintenance. In order to improve the overall equipment efficiency and reduce maintenance costs, regular maintenance and repair of SMT equipment […]

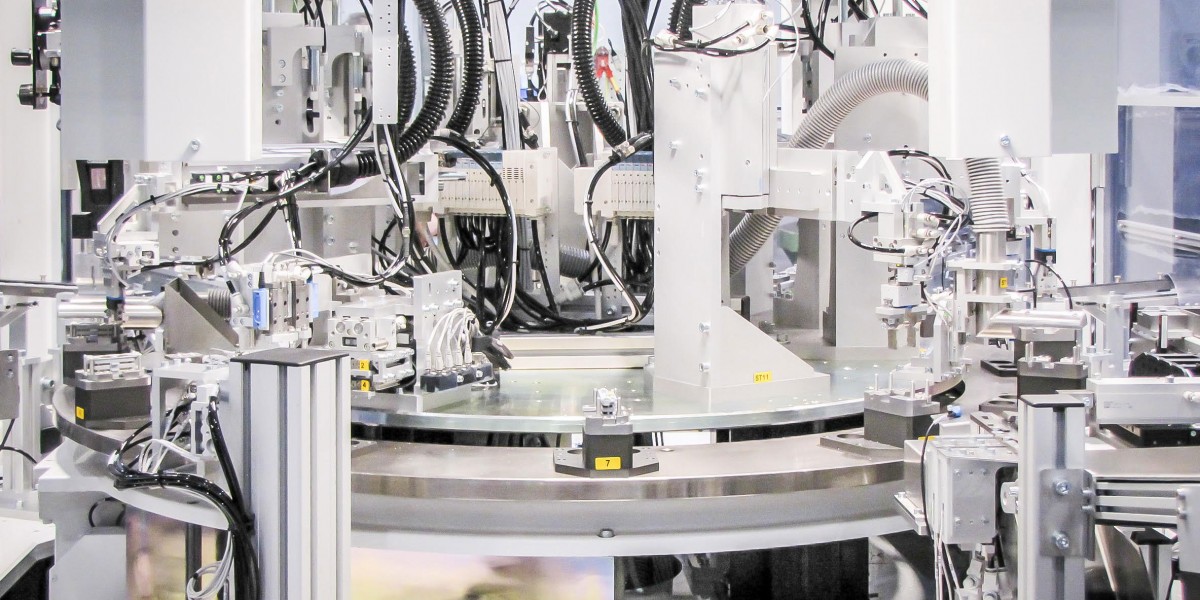

Automated assembly machinery is an excellent choice for many businesses. It streamlines production and allows you to mass-produce in a short amount of time. Assembly machines are carefully calibrated for the fastest and most accurate job. That’s why last-minute modifications lead to poor performance, equipment failure, and frustration from employees and management. Unscheduled shutdowns result […]

Ultrasonic food cutting is a process utilizing knives that vibrate at high frequency. Applying ultrasonic vibration to a cutting tool creates a nearly frictionless cutting surface which provides many benefits. This low friction cutting surface can slice a multitude of food products cleanly and without smearing. Very thin slices are also possible due to the […]

AI can play a vital role in optimizing power and water consumption, which creates immediate benefits for environment, operating costs and margins. For instance, fresh products like fruit and vegetables can vary dramatically in size, shape, color or texture, adding a layer of complexity to the production line. AI solutions can easily recognize variances, removing […]

The maintenance of rolling machine is very important, good maintenance can effectively extend the using life. Customers should pay attention to the plate rolling machine maintenance. Generally, the rolling machine working efficiency and failure rate are closely related to operators. As operators of dangerous equipment, they should know more about relevant knowledge to effectively avoid […]

An Industrial Hardening and Tempering Furnace is a complex system with several working chambers in the harsh environment. It can’t be denied that regular maintenance for this type of machine is a must. Overhaul maintenance for the Hardening and Tempering Furnace is a high load labored process and requires lots of overhaul-based knowledge from the […]

Tiếng Việt

Tiếng Việt