Motion control product manufacturer to license Phoenix Contact’s PLCnext runtime environment. Yaskawa & Phoenix Contact collaborate on next PLC Generation.

The drives, robotics and mechatronics manufacturer Yaskawa and Phoenix Contact has announced that it plans to use Phoenix Contact’s PLCnext runtime control environment as the basis for its next-generation machine controller and PLC platform. The two companies say they have a shared goal moving away from proprietary systems to offer an open and future-proof ecosystem for industrial automation.

Yaskawa and Phoenix Contact announced an agreement to combine Phoenix Contact’s PLCnext Technology with Yaskawa’s i3-Mechatronics concept to development a next generation machine controller and PLC platform, the companies’ said. In short, Phoenix Contact has licensed its Linux-based PLCnext runtime environment to Yaskawa and agreed to further joint developments.

Contents

New Developing Generation of Yaskawa and Phoenix Contact

Yaskawa said it sees PLCnext as the most open industrial automation software platform available. They are combining IEC61131-3 programming, modern programming languages, safety hardware and software and control system security. The company will use the PLCnext technology to further enhance and develop its machine control product offering.

“When PLCnext Technology is combined with the proven motion control engine and robust controller hardware from Yaskawa, it will create a control platform that is open, flexible and powerful. All based on proven PLCopen toolboxes for logic control, machine control and control of delta and articulated arm robots,” said John Payne, Senior Vice President of Motion for Yaskawa America. “This new platform will combine control for logic, motion and robotics with solutions for Industrie 4.0 applications. It will also enhance the control product offering from Yaskawa with solutions for network safety and control system security.”

How it works – Yaskawa and Phoenix Contact Combination

The new controller platform will be based on a new hardware and new software. This includes a motion control engine, PLCopen building blocks and a high-end machine controller. The hardware, developed by Yaskawa, will use Asics (custom chips) designed by Yaskawa’s German-based Profichip business. And the new products will be branded with the Yaskawa name.

The partnership with Phoenix will not affect products from Vipa Controls, Yaskawa’s German controls business in which it took a controlling share in 2012. Vipa merged with Yaskawa Europe last year.

Armin Schlenk, Yaskawa Europe’s director of marketing for the EMEA region, told Drives & Controls that the current Vipa portfolio, such as its high-speed System Vipa 300S, Vipa SLIO PLC and I/O System, the VIPA Micro compact PLC, and Vipa HMIs, are not affected by the new partnership with Phoenix.

“We will continue to fully support our S7-compatible products … and offer our customers the best support as well as the availability over many more years to come,” he says. The Vipa portfolio will be “further developed according to the technological requirements of the market”.

Features

Yaskawa regards PLCnext as “the most open industrial automation software platform available today”. It combines IEC 61131-3 programming, modern programming languages, safety hardware and software and control system security. It will use PLCnext to further enhance and develop its i3-Mechatronics machine controls portfolio.

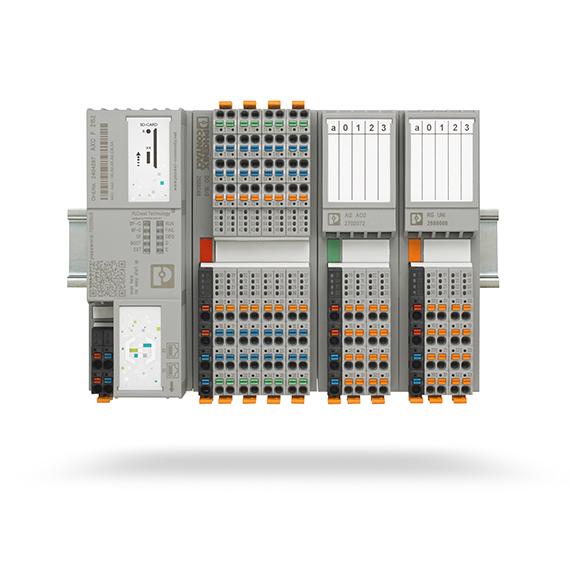

Phoenix first announced the Linux-based PLCnext platform at the 2016 SPS show in Germany. They describe it as an open control platform that would “allow engineers from different disciplines to work together simultaneously on projects, each in their preferred development environments”.

The first products were launched a year later with Phoenix’s then chief technology officer, Roland Bent, hailing the development as “the start of a new era in automation”.

PLCnext combines open control technology, modular engineering software and an online community, and is designed to adapt easily to changing requirements. The platform includes a digital marketplace for software as well as supporting cloud integration.

Conclusion

“The openness of the PLCnext ecosystem enables a large number of providers to offer highly flexible, secure, and modern automation technology,” says Ulrich Leidecker, COO and president of Phoenix Contact’s industrial management and automation business. “This technology partnership with Yaskawa is a milestone for the automation industry. Due to the fact that the more partners that engage in an open automation ecosystem, the more beneficial it becomes for every single participant.”

John Payne, senior vice-president of motion for Yaskawa America argues that combining PLCnext with Yaskawa’s proven motion control engine and controller hardware “will create a control platform that is open, flexible and powerful. All based on proven PLCopen toolboxes for logic control, machine control and control of delta and articulated arm robots. This new platform will combine control for logic, motion and robotics with solutions for Industrie 4.0 applications. It will also enhance the control product offering from Yaskawa with solutions for network safety and control system security.”

Source: Drives And Control

Tiếng Việt

Tiếng Việt