Ultrasonic food cutting is a process utilizing knives that vibrate at high frequency. Applying ultrasonic vibration to a cutting tool creates a nearly frictionless cutting surface which provides many benefits. This low friction cutting surface can slice a multitude of food products cleanly and without smearing. Very thin slices are also possible due to the reduced resistance. Foods containing items such as vegetables, meats, nuts, berries and fruits can be cut without deformation or displacement of the internal product. The low friction condition also reduces the tendency of products like nougat and other soft candies from sticking to the cutting tools, resulting in more consistent cuts and less down time for cleaning. And because of the advanced process control that is available in ultrasonic generators, cutting performance can be easily manipulated by simply adjusting the equipment parameters.

Contents

Types of Foods

Ultrasonic food cutting systems are often used to cut the following types of foods:

- Hard and soft cheeses, including products containing pieces of nuts and fruit

- Sandwiches, wraps, and pizzas for catering industries

- Nougat, candy bars, granola bars and healthy snack bars

- Semi-frozen meats and fish

- Breads or cake products

Components

Every ultrasonic food cutting system is comprised of the following components:

- An ultrasonic generator (power supply)

The ultrasonic generator converts the 110VAC or 220VAC electrical supply current into a high frequency, high voltage electrical signal.

- An ultrasonic converter (transducer)

The ultrasonic converter utilizes the high frequency electrical signal from the generator and converts it into linear, mechanical movement. This conversion

occurs through the use of piezo-electric ceramic disks that expand when a voltage is applied. The converters used for food cutting systems are specifically designed to be completely sealed for operation in wash-down environments and incorporate air in and out ports for cooling.

- An ultrasonic booster

The ultrasonic booster is a tuned component that mechanically adjusts the amount of linear vibratory movement from the converter to the required level

for the specific application to produce optimal cutting performance. The booster also provides a safe, non-vibrating location to clamp onto the cutting tools. Boosters used in food cutting systems should be a one-piece, solid titanium design for maximum cutting accuracy and repeatability. In addition, the single piece design allows for a thorough wash-down, unlike multi-piece ultrasonic boosters that can harbour bacteria.

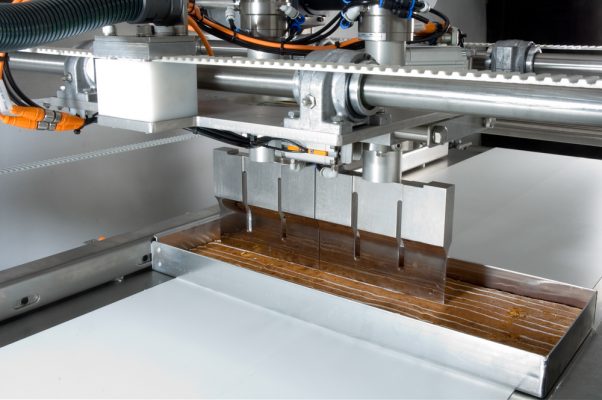

- An ultrasonic cutting tool (horn/sonotrode)

The ultrasonic cutting horn is a custom made tool that is engineered to vibrate at a specific frequency. These tools are painstakingly designed using computer modelling technology for optimum performance and longevity. Ultrasonic tools must be tuned to match the frequency of the system. This tuning procedure requires consideration of the horn’s mass, length and geometry. Titanium is the material of choice for ultrasonic tools because of its resonance and fatigue resistance properties. Titanium is also compatible with the sanitary requirements of the food processing industry. Due to the high stresses inherent in the thin blade geometries required of ultrasonic cutting horns, manufacturing should be done using a wire EDM technique and subsequent stress relieving process in order to maximize the life of the tools.

- A material handling system

Automated machinery is required for the proper positioning and movement of the food products and ultrasonic tools. Automation is critical in achieving the correct location, direction and rate of cut. Typically, these handling systems utilize servo drive mechanisms for precise control of speeds and positions of the food products and/or cutting tools.

Food Cutting Process

Factors to be considered in the food cutting process:

- Initial Vibration Timing

Ultrasonic cutting horns can be challenging to design and manufacture due to the narrow blade designs required. Vibrating the tools at full amplitude while

not under a load can sometimes cause premature failure. Therefore, the signal from the ultrasonic generator should be timed properly with the automated machinery so that the tools reach full vibration just before the cutting edge meets the food product. Vibrating prior to contact is necessary to avoid deformation of the food product that would be caused by contact from a nonvibrating cutting surface.

- Vibrational Amplitude

The term ‘Amplitude’ describes the microscopic distance of vibration of the cutting surface of the horn. Amplitude is adjusted mechanically by the booster, as well as digitally by the generator. The degree of amplitude has an effect on the cutting process and must be adjusted to suit the needs of each application. Softer foods and those containing a variety of textures typically require higher amplitudes. Examples are:

Soft candies and nougat

– Soft cheeses and those containing nuts or pieces of fruit

– Products that contain various hard and soft ingredients such as sandwiches and wraps

– Cakes and breads

Firm food products often have lower amplitude requirements. Examples are:

– Frozen foods

– Firm cheeses

– Vegetables

- Cutting Velocity

The speed at which the cutting tools enter and proceed through the material being cut is also a process variable that should be optimized for each application. It is sometimes necessary to penetrate products with a crust slowly to avoid deformation and then increase the velocity of the knife within the product in order to achieve the best cutting results.

- Final Vibration Timing

Depending upon the consistency of the material being cut, the finished slices may tend to stick to the side of the cutting horn after the ultrasonic vibration

has been turned off. Therefore, maintaining the ultrasonic vibration while the tools are being withdrawn from the product can utilize the friction-free properties to release the cut slices more cleanly and consistently.

Typical Customer Concerns

Typical customer concerns regarding ultrasonic tooling:

- How long will the ultrasonic cutting horns last?

Sonics and Materials, Inc. manufactures using a unique wire EDM technique and subsequent stress relieving resulting in tools with reduced material stress

which enhances their service life. Typical Sonics cutting horns last for years of operation before the fatigue properties of the titanium become an issue.

- What can I do to get the longest life from the cutting horns?

Incidental contact of the cutting tools with metal parts such as trays, belts or other non-food materials can damage the cutting edge. This type of misuse is

the most common cause of ultrasonic horn damage. Proper automated machine programming and good maintenance practices can greatly extend the life of cutting horns.

Operating cutting tools with excessive amplitude will cause premature failure of the horn due to the additional fatigue stresses that result. This is typically

caused by the use of an improper booster within the system.

- Is it necessary to re-sharpen the cutting horns?

With ultrasonic technology, the sharpness of the cutting edge is not as critical as it is for mechanical knives. In fact, many ultrasonic cutting horn designs

incorporate a small flat on the cutting tip to extend tool life and enhance performance. The vibratory motion provides much more of the cutting effect

than the sharpness of the tools.

If proper operating techniques are used and accidental tool collision is avoided, re-sharpening is generally not required for many thousands of operating hours. (If ultrasonic tools do become worn or damaged, they should be returned to Sonics for re-sharpening and retuning.)

Ultrasonic food cutting may be suitable for a certain number of food cutting operation. However, high frequency vibration applied to cutting tools does provide significant benefits. Primarily, ultrasonic technology enhances the cut quality and consistency, and offers the ability to cleanly slice multi-textured food products without deformation.

Tiếng Việt

Tiếng Việt