PLC programs are never final, it is always possible to make corrections and subsequent adaptations to new system according the customer requirements. Even during commissioning, program changes are often necessary.

The commissioning of a system can be divided into four steps:

- Checking the hardware

- Transferring and testing the software

- Optimization of the software

- Commissioning of the entire system

Contents

1. Checking the hardware

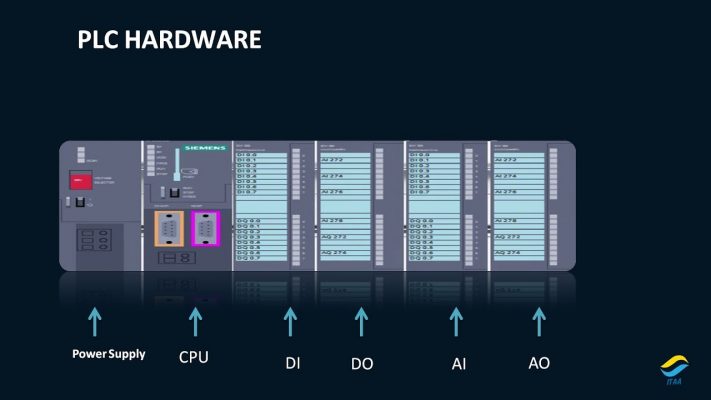

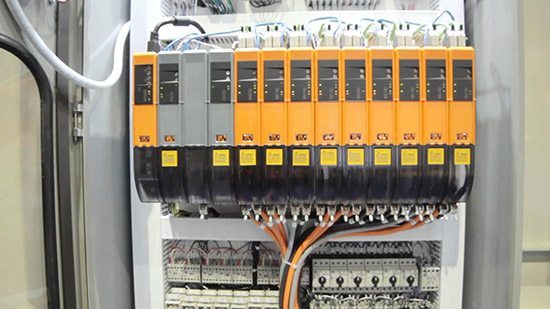

Each sensor, switch and button is connected to a specific input and each actuator to an output. During engineering process addresses and wires must not be mixed up. Also, the sensors and actuator placing should be checked (that they are where they have to be in the automated system).

During checking procedure, the outputs are set in a test mode. The actuators must then meet the specified requirements (functions). If changes are made, then the documentation (allocation list, drawings, etc) must also be updated to respond to reality.

Testing inputs and outputs

Input devices, e.g. switches, can be manipulated to give the open and closed contact conditions and the corresponding LED on the input module observed. It should be illuminated when the input is closed and not illuminated when it is open.

Failure of an LED to illuminate could be because the input device is not correctly operating, there are incorrect wiring connections to the input module, the input device is not correctly powered or the LED or input module is defective. For output devices that can be safely started, push buttons might have been installed so that each output can be tested.

2. Transferring and testing of software

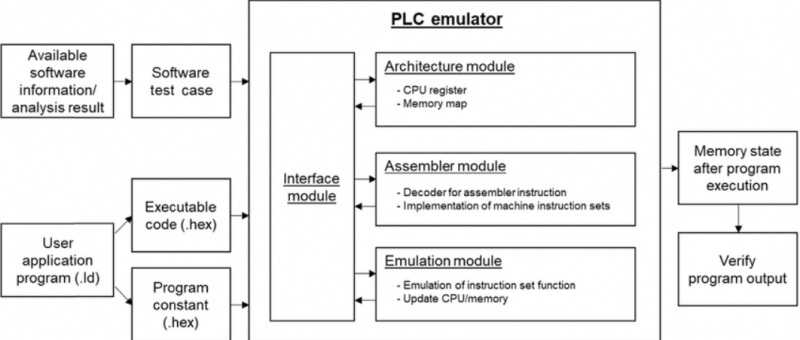

Prior to commissioning, all available off-line and virtual PLC program testing tools should be used intensively to find program faults. For example, such test tool is in STEP 7 as subprogram S7-PLCSIM. It simulates the work of a PLC (virtual PLC) and allows the user written PLC program to be tested.

The user has to simulate the input signal changes and verify how the outputs react to it. Some PLCs offer simulation in a real PLC: the entire program is executed in a PLC without the real inputs and outputs being connected. Processing of the PLC outputs thus only takes place in the PLC image table. The physical PLC I/Os are not updated to/from the PLC I/O images.

Therefore this eliminates the risk of damaging machines or system parts.

After this, the individual user program parts and system functions are tested: manual operation, setting, individual monitoring programs etc. and finally the interaction of the program parts with the help of the main program.

The system can and should be commissioned step-by-step. Important aspects of commissioning and fault detection are the test functions of the programming system, such as the single-step mode or the setting of stop points. The single-step mode in particular is of importance, whereby the program in the PLC memory is executed line-by-line or step-by-step. In this way, any program faults which may occur in the program can be immediately localized.

3. Optimization of the software

User programs can almost always be improved after the first test run. It is important that any corrections or modifications are made not just in the PLC user program, but are also taken into account in the documentation.

4. Commissioning of the entire system

This already occurs in part during the testing and optimization phase. Once the final status of the PLC user program and the documentation is established, all the controller functions (in accordance with the automation task) need to be executed step-by-step again.

If no faults occur by the entire system commissioning, then the system is ready to be handed over to the customer.

Reference:

- Application of PLC industrial automation – AutoMatic

- Programmable Logic Controllers by W. Bolton

CTI SUPPLY – THE RIGHT INDUSTRIAL AUTOMATION SYSTEM INTEGRATOR

CTI SUPPLY built up a group of well-qualified senior engineering teams with a great number of in-house experts and PLC programmers in Vietnam. We are available to take on different projects in scale, even on short notice, and quickly ramp up by working as an extension of your internal team. Our vast experience allows us to offer custom and application specific training as an added benefit to our clients.

With over years of experience in high-tech machine programming, CTI SUPPLY’s design team are able to simplify SCADA prototype process as our main package of your choice. We can also supply you with drawings and documentation for all your equipment builds.

Engineered Solutions | Custom Control Systems | Programming Services

During the current economic uncertainty, CTI SUPPLY is still open for business to offer our full offsite service globally.

Hotline: (+84) 91 190 1717, Email: info@ctisupply.vn

Tiếng Việt

Tiếng Việt