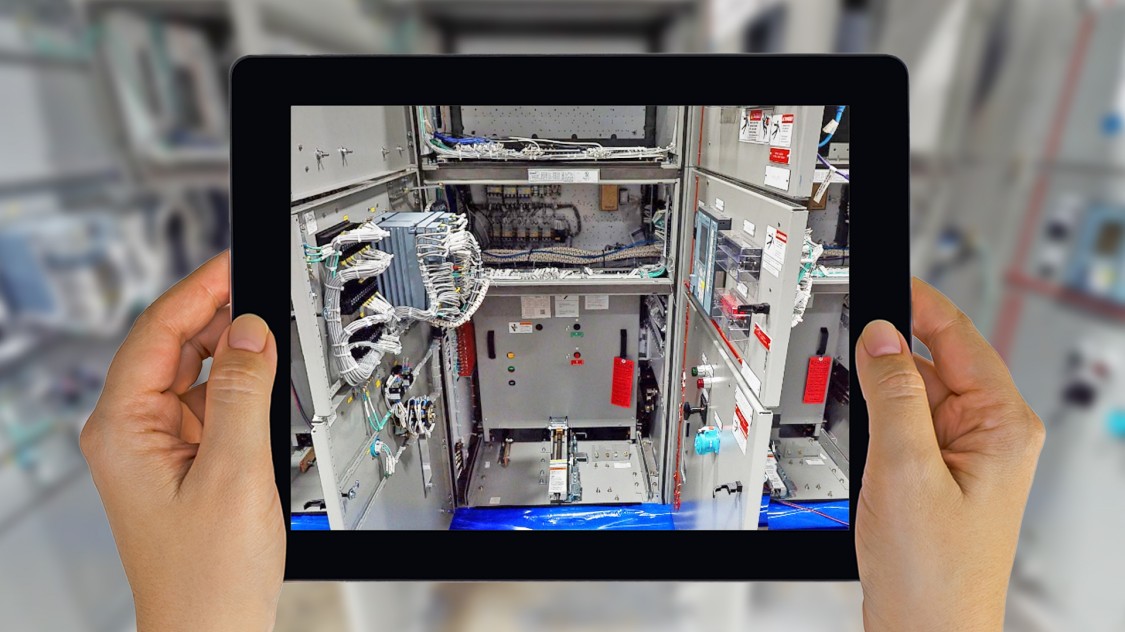

FAT (Factory Acceptance Test) is carried out in order to demonstrate that the system and its components function properly, that manufacturing, assembly, configuration and software generation are done correctly and that system performance is in compliance with the approved functional specifications and relevant documents. The same should be also carried out for DCS. The main […]

Tag Archives: DCS

Safety in Automation Systems By increasing productivity while battling a reduced skilled labor workforce, automation has given businesses an essential tool to be successful. However, while pushing these boundaries to advance ourselves, we must always remember that people are essential and must be protected. While great advancements occur to push a company’s overall yield, safety […]

PLC, SCADA and DCS systems Originally PLC, SCADA and DCS systems were supplied by separate manufacturers. Today the top 3 PLC companies Siemens, Rockwell and Schneider are in the top 5 of SCADA suppliers and are also in the top 7 of DCS manufacturers! Using different products but often with common I/O, controllers and sharing […]

The industrial automation peaked when you use automated control like Programmable Logic Controller (PLC), Computer Numerical Control (CNC), Remote Terminal Unit (RTU) etc. They help in controlling industrial processes and machinery, replacing manual intervention and dangerous assembly operations, which are automated. Functional Elements of Industrial Automation Industrial Automation consists of an array of elements, which […]

Tiếng Việt

Tiếng Việt