IO-Link is a universal, intelligent enabler of technology. Yet its value for control system architectures is its ability to provide fieldbus-neutral, point-to-point connections. In other words, IO-Link Plays Continuous Part in Automation System Architectures.

Contents

Emergence of IO-Link Using

Use of IO-Link has emerged as an industrial technology trend. It is enabling a wide range of control architectures to implement fast, flexible and efficient production, and to achieve the connectivity required for Industry 4.0. Moreover, its hallmark is ease of use by making the installation and exchange of new devices easier and guaranteeing error-free data transfer.

.jpg) |

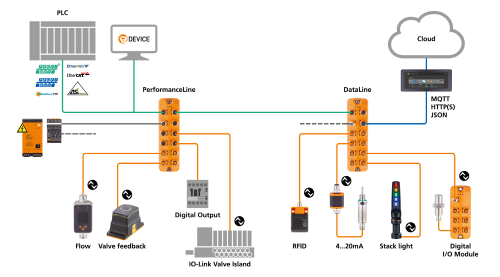

| An Example of IO-Link system architecture. (Image source: IO-LINK) |

IO-Link is built on a simple to use, but powerful industrial automation standard (IEC 61131-9) for setting up intelligent solutions. It provides an effective digital interface for implementing fieldbus-neutral, point-to-point connections. It provides globally-recognized, standardized IO-technology for communicating from automation controllers to low-level devices, integrating sensors along with actuators at the fieldbus level.

With over 12,000 devices, the IO Link IODDfinder has become an effective Internet platform for IO-Link description files by leveraging a centralized, cross-manufacturer database. Using this service, provided by the IO-Link member community, files arrive from the Internet automatically.

According to IO-Link, the database hosts more than 7,500 description files from around 80 manufacturers. This makes it the world’s largest collection of IODDs. By joining the community, each member gets the opportunity to create a manufacturer account in IODDfinder, and the ability to upload description files for their devices.

IODD Features

The platform provides a web front end which can be used to search for and find IODDs for individual devices. Actual added value comes from application program interfaces (APIs). On this, device manufactures can use to automatically upload, update and manage a large number of IODDs. The goal is to make the central database complete with content that is always up to date.

Description files can be downloaded automatically using APIs. This allows software tools to access the database over the Internet for device configuration or integration into automation systems, for example. A majority of downloads are now carried out using such tools. Each IO-Link device features its own device ID and a specific manufacturer ID.

Software tools can be used to read out these two identification numbers immediately after connecting to IO-Link devices, and download the appropriate description file automatically from the Internet.

Connectivity with CIP Architectures

Enhancements to the EtherNet/IP™ specification which outline how to integrate IO-Link devices into CIP™ (Common Industrial Protocol) architectures has also been announced by ODVA. This allows IO-Link sensors and devices at the lowest level of the network to be better connected with EtherNet/IP controllers and devices at higher levels of the network.

“IO-Link device integration with CIP provides seamless communications between CIP originators and IO-Link devices through the intermediate IO-Link master, all using existing IO-Link hardware and standards.”

Changes to the specification are seen to reduce engineering effort in integrating IO Link and easier acquisition of data and information. IO Link devices are recognized within EtherNet/IP without the end user needing to worry about data conversion. One key benefit is that an IO-Link device is viewed as a native CIP device sitting on a (virtual) subnet.

An IO-Link Master provides CIP for the IO-Link device, transparent to the originating CIP application. All types of IO Link communication (cyclic, acyclic, and events) are mapped to CIP. CIP to IO-Link communication is possible using the I-Link master and device specification standardized within IEC without changes. Direct communication is enabled via translation between CIP originators and IO-Link devices through the intermediate IO Link master. All IO-Link devices are treated as if they were CIP Connection target devices (I/O Adapters) on a virtual IO-Link subnet.

CTI SUPPLY – THE RIGHT AUTOMATION SYSTEM INTEGRATOR

CTI SUPPLY built up a group of well-qualified senior engineering teams with a great number of in-house experts and PLC programmers in Vietnam. We are available to take on different projects in scale, even on short notice, and quickly ramp up by working as an extension of your internal team. Our vast experience allows us to offer custom and application specific training as an added benefit to our clients.

With over years of experience in high-tech machine programming, CTI SUPPLY’s design team are able to simplify SCADA prototype process as our main package of your choice. We can also supply you with drawings and documentation for all your equipment builds.

Engineered Solutions | Custom Control Systems | Programming Services

During the current economic uncertainty, CTI SUPPLY is still open for business to offer our full offsite service globally.

Hotline: (+84) 91 190 1717, Email: [email protected]

Tiếng Việt

Tiếng Việt