PROJECT

Industrial Automation

Automation system for multinational corporations, high-tech automated manufacturing plants and the oil and gas industry

System Integrator

Programming Control System, Plant Processing and System, Engineering Installation, Testing and Commissioning of Instrument

Remote Commissioning

Virtual solutions to save the travel/onsite cost, serve for clients sufficiently and implement the project in programming and commissioning tasks

How it Works

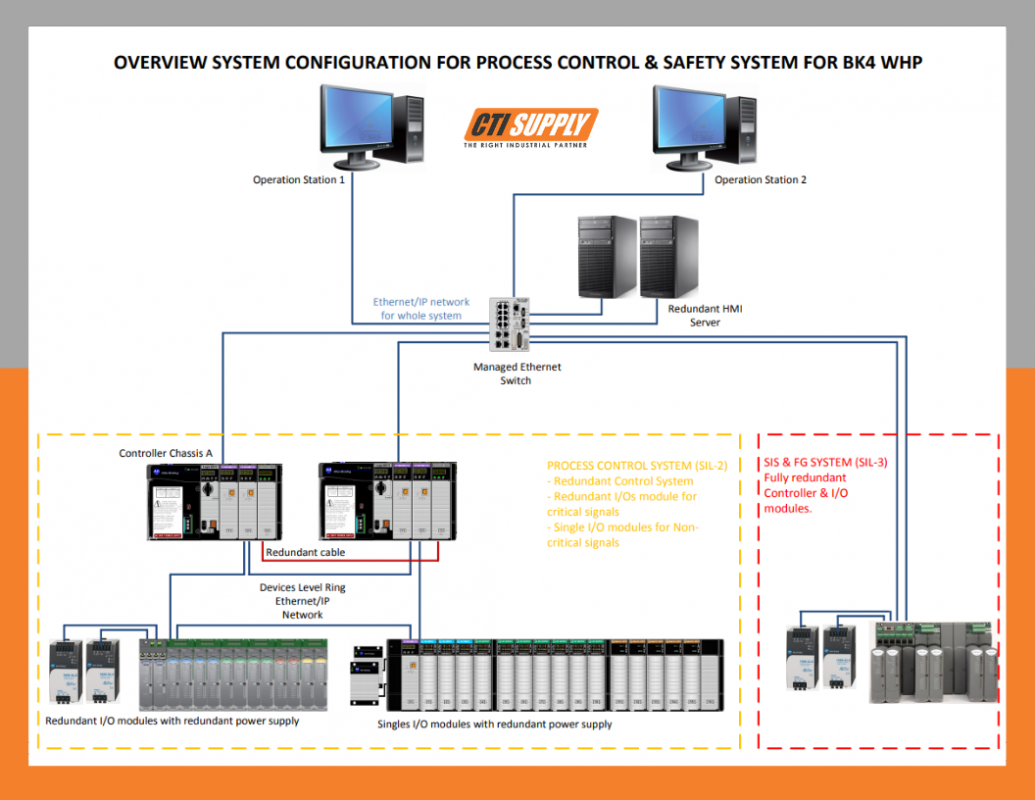

Safety Instrumented System for Oil Rig

Safety Instrumented System for Oil Rig BK 4/BK 4A – Vietnam

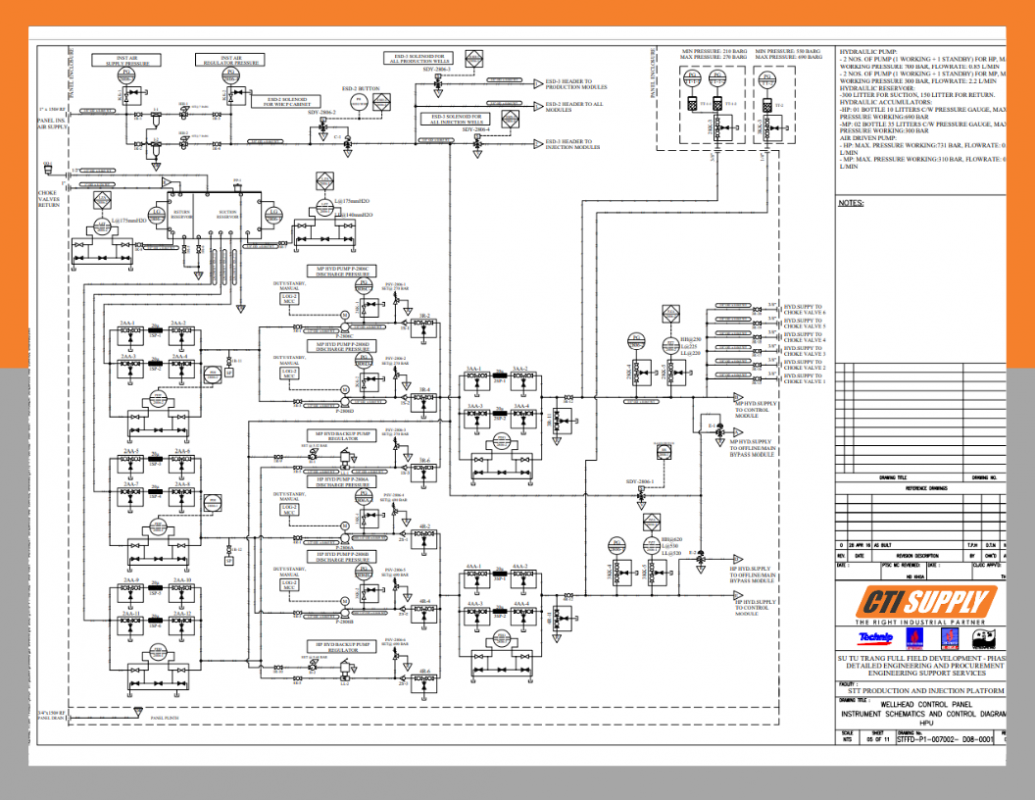

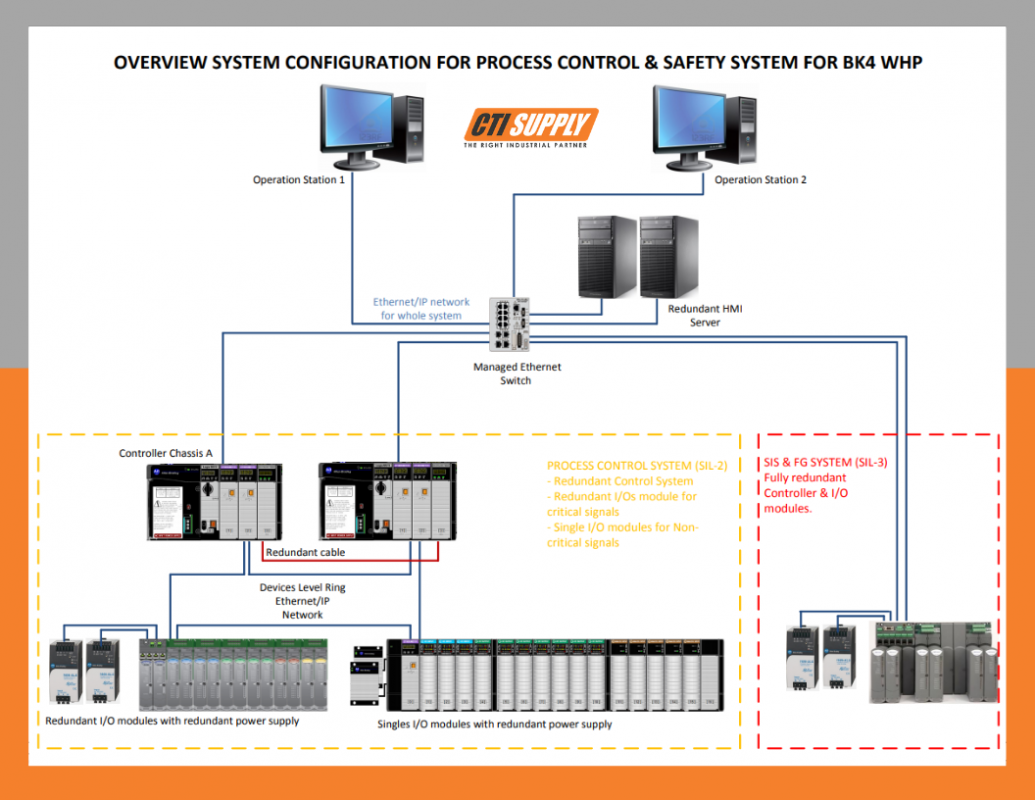

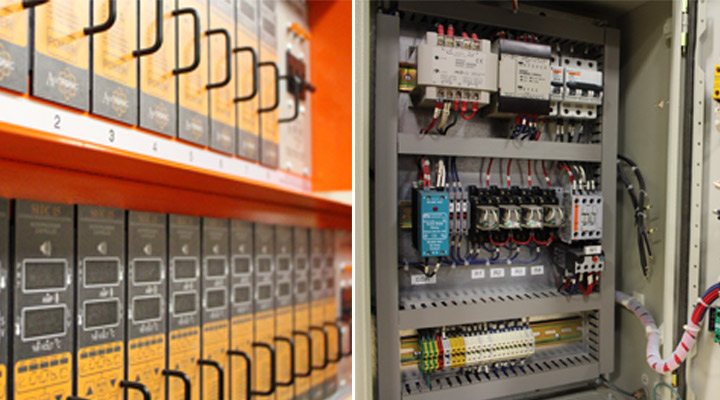

CTI SUPPLY engineers concentrated on designs from system architecture, electrical and construction drawing and cabinet assembling for 3 units in details.

The safety instrumented system manages safety and fire & gas of the BK-4 drill rig and satellite platforms. Under total 300 I/Os, the system monitored safety process parameters including pressure, level, temperature, control verious instruments e.g. shutdown valve, blowdown valve, fire and gas detector, firefighting water pump.

The highlights that make this system more intensive is Full redundant and fail-tolerance design achieving oil and gas SIL 3 according to IEC 61511 standard.

What are software applications to build up the system? The system was designed with AAdvance PLC, SCADA and Factory Talk View.

WIP 40000

The system monitors safety process parameters including pressure, level, temperature, control verious instruments e.g. shutdown valve, blowdown valve, fire and gas detector, firefighting water pump.

The key designs are system architecture, electrical and construction drawing and cabinet assembling in details.

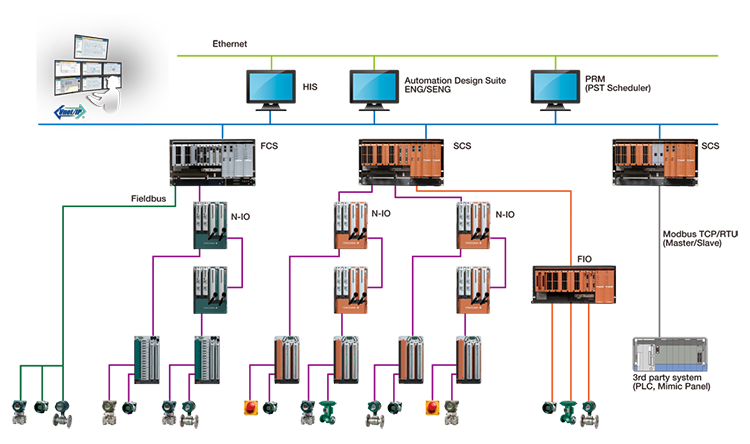

The PLC is Yokogawa Prosafe RS with 900 instruments and Addressable fire addressable panel of Autonica. This system has Full redundant and fail-tolerance design achieving oil and gas SIL 3 according to IEC 61511 standard.

WIP 40000

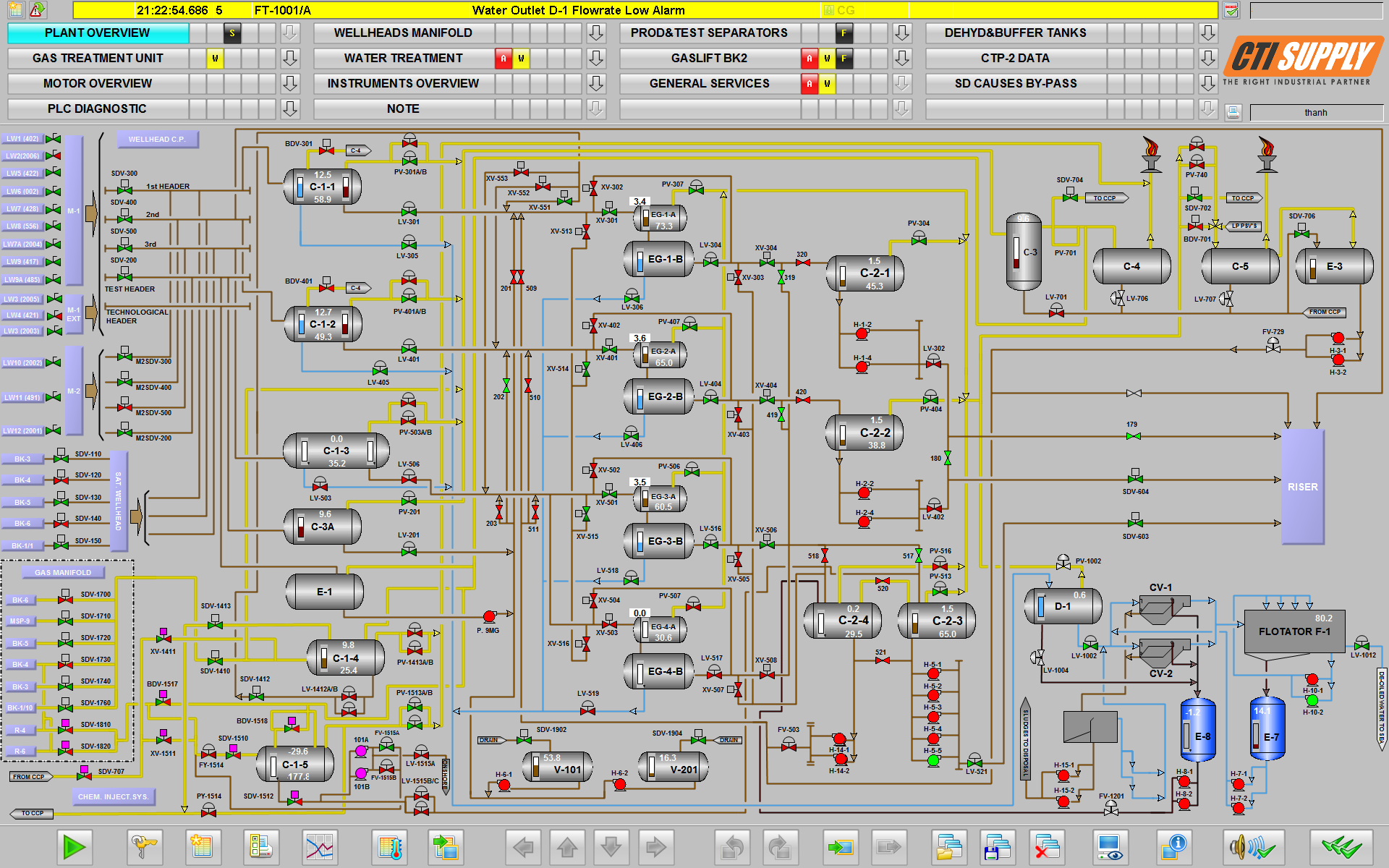

MODIFICATION OF CPP-2 PLATFORM

MODIFICATION OF CPP-2 PLATFORM

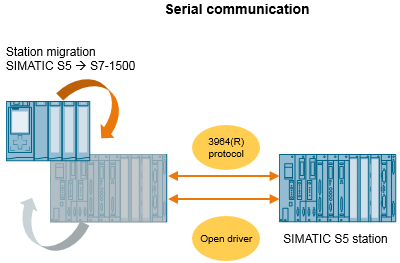

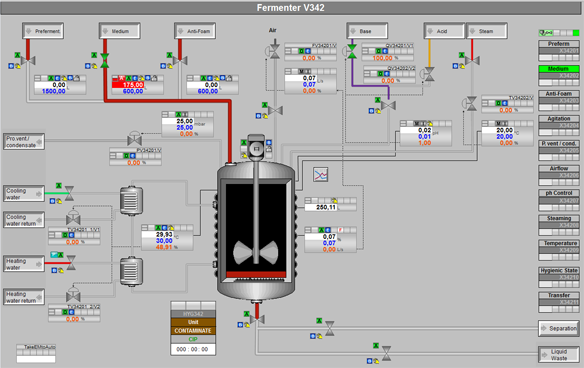

The main tasks that CTI SUPPLY performed were upgrading both the software and hardware of central processing platform of VS from Siemens S5 to S7 based on PCS7 with version 7.1.

This 3000-I/O scale project took the team a year to draw up the plan and 10 days to do commissioning and handover. For the hardware, we did reconnect the field cabling, removed old units, installed new units, made commissioning and started it up.

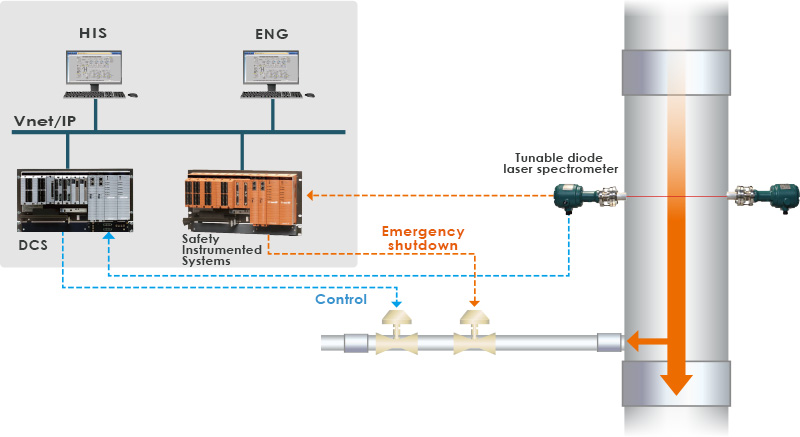

ICSS BK TNG ESD SYSTEM – EMERGENCY SHUTDOWN SYSTEM

The system with over 1000 instruments was built to monitor the safety process parameters regarding to pressure, level, temperature, control verious instruments e.g. shutdown valve, blowdown valve, fire and gas detector, firefighting water pump.

CTI SUPPLY programmers developed system architecture, electrical and construction drawing to and cabinet assembling for 3 units which run on to DCS PCS7 version 8.1 platform.

ICSS BK TNG ESD SYSTEM

Tiếng Việt

Tiếng Việt